The Result

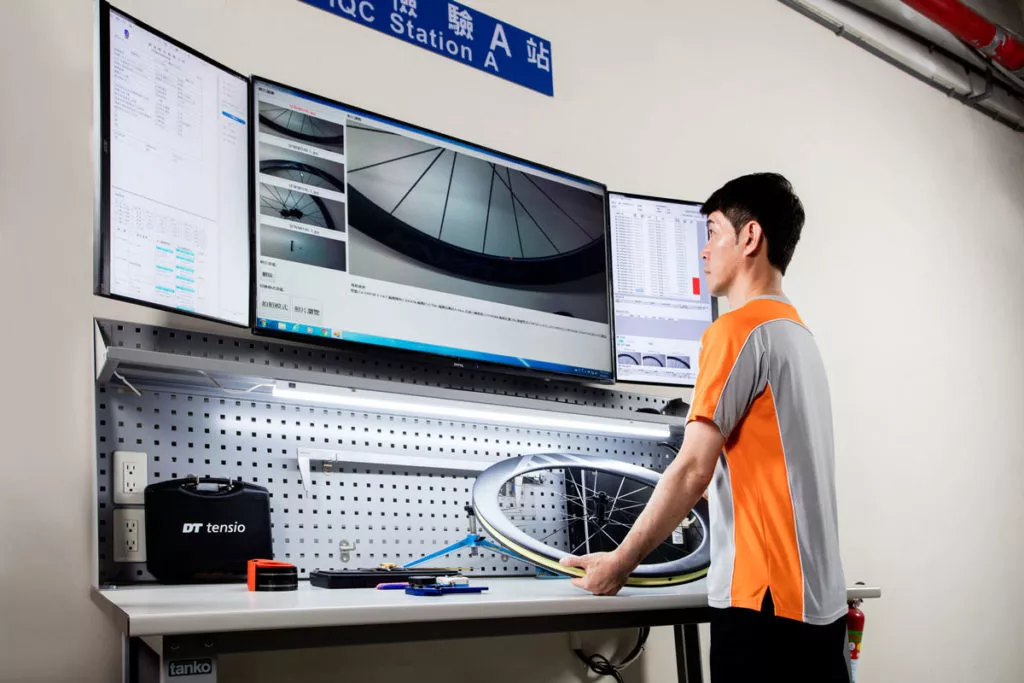

In this way we can instantly identify order statuses and our engineer’s interaction with each part of the process.

Our process steps are timed, outputting data to allow management to easily optimize process flows and identify areas where further improvements can be made.

This is especially critical for the more complex units such as E Bikes where the number of parts and testing required are greater and require different skill sets in assembly.

Proprietary Electronic

Management Systems

Constantly Optimized Processes

Correctly Skilled

Assembly Staff

Skilled Staff

Staff undergo constant and specific training programs on a range of skills and these are recorded in their electronic profile.

We always ensure that only staff trained for the assembly of a type of bicycle or component are assigned to work in that area.

This significantly increases production efficiency and output whilst reducing production errors and wastage.

Optimizing Production

Material Flows

Automated Storage &

Retrieval Systems

Automated & Concealed Material Transportation Systems

Clean, Safe Working

Environment

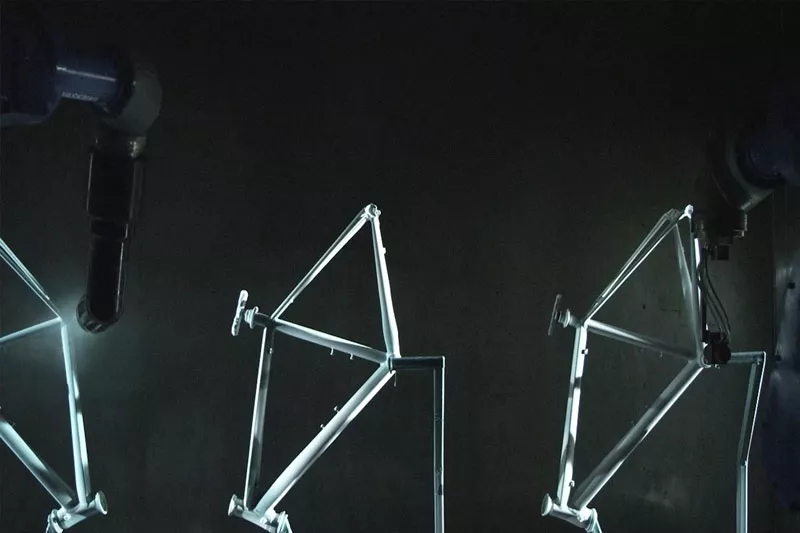

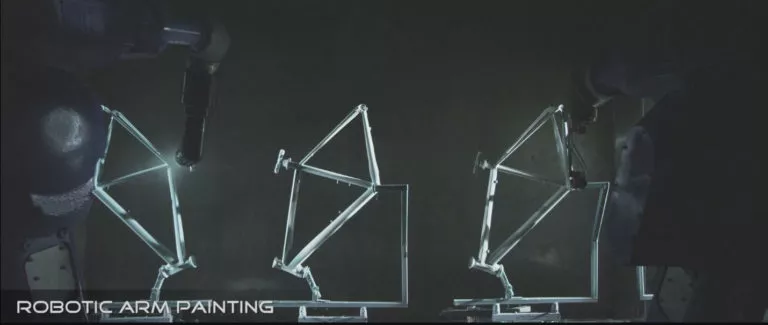

Painting & Decaling

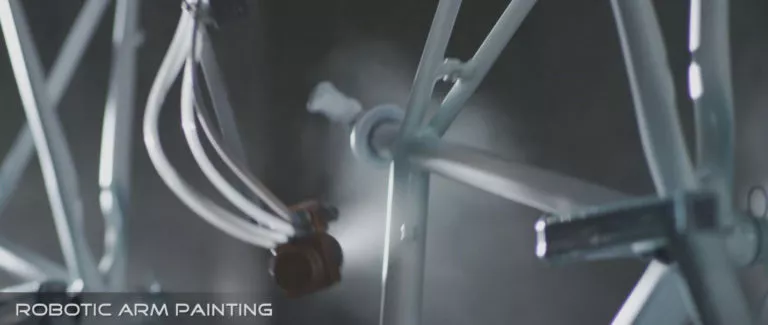

For the most efficient and stable production we have invested in advanced, fully automated systems wherever possible. All our mass market frames are delivered through automated (AGV=automated guided vehicle) conveyors to our robotic paint shop, where our automated robotic painting arms deliver perfect, efficient painting.

For more customized products we have separate hand painting and decaling shops that cater to higher end products or those with smaller quantities and more complex requirements.

The Future

E-commerce Systems

Whilst many of our customers operate with FJM through a B2B business model, we now offer complete B2C customized bike systems for customers as well.

E-bike

Smart E-bike Manufacturing

With new trends in E-bike design and functionality constantly changing, FJM offers production flexibility and rapid time to Market for e-bike manufacturing